A treasury of carefully horded ambition and inspiration. A fragile accumulation of flimsy paper, so thin as to need handling with a held back breath. Soft blue or yellow lines impressed on tissue, meant to be transferred with the gentle application of heat. Images of flowers and swirls of design, intended for interpretation – held and preserved for decades. All tucked away in paper shells, layered up and stored as ideas and opportunities – most unrealised, but some revealed in equally fragile card, pierced with pins and dusted with pounce or chalk.

Category: Snippets of History

Notes on historical aspects of costume, fashion, textiles and stitchery – as worn, worked, woven and washed …

The Sweating System – The Employer’s Point of View

(see http://www.mythweaver.co.uk/stitchery/snippets/stitch-stitch-stitch-in-poverty-hunger-and-dirt/ for details of the conference at which this talk was presented)

Fashion Slaves

(see http://www.mythweaver.co.uk/stitchery/snippets/stitch-stitch-stitch-in-poverty-hunger-and-dirt/ for details of the conference at which this talk was presented)

Clothes and Disease 1830- 1889

A detailed look at how disease was spread through clothing, old and new, to all strata of society.

Notes from a talk by Lou Taylor.

Following 1840’s ‘Song of the Shirt’ there was a widely held belief that disease was spread through clothes. Medical research was not widespread. Prevalent diseases: Typhoid, Diphtheria, Diarrhoea, Cholera, Whooping cough etc. No-one could pinpoint contagion.

Robert Gough and Louis Pasteur introduced idea of bacteria.

Writing of the period tells us what people thought.

Henry Mayhew – Evening Chronicle, 1849 Bermandsey Tour (large % of population working class) guided by doctor, where a Barber had Scarlett Fever, then Typhus. Child died of Cholera, wife now ill of it. Workshop was dining room with seepage from neighbour’s privy soaking through wall. Drinking water drawn from river.

1849 (Mayhew) Tailor dying of consumption but his clothes and bedding pawned. Covered with a coat, newly made, which was to go to shop the next day.

C. Kingsley 1848. Cheap, nasty clothes. When clothes pawned workers used the clothes they made to cover them at night. Children with Cholera covered with a half-finished riding habit.

Therefore: new clothes could spread disease.

1872 John Thompson’s London features 2nd hand clothes shops and pawn shops. Both shops could receive diseased clothes and pass them on.

Where living conditions were poor, washing almost impossible.

Mayhew, 1849. Sheets been on beds nearly 3 months. No clean shirt this month. Could not afford to pay for washing. Scarce a house without yellow linen hanging out to dry over water (stained with sulphur).

Germs could live in clothes or toys for several years. Dead child’s toys could pass on scarlet fever.

In 17th century the plague was spread by infection in bales of cloth, especially silk.

In 1665 regulations re fumigating bedding were announced.

Pepys kept a new wig several months before wearing it because of plague.

1777 Dr Mead. Disease could be spread through dirt in clothes, food etc.

By early 19th century cholera came to England from India. Spread across Europe – Novogorod 1829, Poland 1831, Hamburg 1831. College of Physicians decreed quarantine for boats carrying flax.

Oct 1831 Cholera in Sunderland. 2nd epidemic 1840s (coupled with Typhus – brought in by starving Irish settlers)

(Good book – Whimsloe: The Sources and Modes of Infection.)

Many 19th century people believed that Cholera was spread through the air. ‘Miasma.’

Slums bred diseases, but upper class also died (Prince Albert!) Therefore people began to think of drains. By mid-19th century preventative measures being taken. Limewashing and disinfection of drains.

However, the real causes of disease not known.

Lou Taylor was Senior Lecturer in Dress and Textile History at Brighton Polytechnic. Chairman of the Textile Society and author of ‘Mourning Dress, Costume and Social History’

The Beaders

An updating of a short paper read at the first Costume Society Symposium, London, April 19th.

Notes from a talk by Joan Edwards.

Two ways of Beading:

- Sewn on with needle (bead embroidery)

- Worked before making up

Formed into ornaments and then sewn on.

- Added after making up.

Bead embroidery (1) is very skilled. Bead work (2) is unskilled.

1904 Berlin exhibition to show exploitation of home workers. Taken up by London clergyman who made up his own exhibition in Church Hall.

1906 another German exhibition featuring evidence gathered. Many workers hesitant to send examples for exhibition for fear of losing jobs.

Women’s Industrial Council received report on embroidery as a home work (Included beaders and artificial flowers). Some cases of middlewomen, who finds workers and then pays them. Worker reluctant to give evidence. 14-15 hours a day needed for a living wage – i.e. 1shilling 1 ½ average. The posture needed for work caused bad eyesight and nerves.

2 May 1906 Daily news Sweated Industry exhibition. Showing workers in action. 30,000 visitors by 29th May at 1 shilling entry each.

Fashion fluctuation makes trade varying. Low wages or no wages. Beading trying on eyes.

Women’s Industrial Council 1907 published a hardback on ‘Sweating.’

1907 Sweated Industries exhibition in Oxford opened by Viscount Milner.

1913 Glasgow. Scottish Council for Women’s Trade – exhibition on ‘Sweating’ entitled ‘The Song of the Shirt.’

Beaders persuaded to take part, nameless, on stand 10. Number 19 worked beading on shoes – was paid 6 shillings a week, worked 12 hours per day, had to provide her own needles. Number 20 earned 5 shillings per week making beaded ornaments, had to fetch work (3 hours walking) – cut out buckram, bind it, sew on beads. Work bad for eyes.

Exploitation still exists. Bengali workers in London, Brick Lane.

Joan Edwards had just published the sixth of her small books on the history of Embroidery (The Bead Embroidered Dress) and was writing a biography of Dorothy Benson who worked for forty years in the Embroidery Department of the Singer Sewing Machine Company.

Shirtmaking

Sweated labour in the shirt trade was one of the first areas in which it caught public attention; in the early 1840s the celebrated court case Moses V the Widow Bidell concerned shirtmaking and so, of course, did Hood’s ‘Song of the Shirt.’ This talk traces the trade’s development through the 19th century.

Notes from a talk by Sarah Levitt.

1843: The Song of the Shirt – best known poem of the 19th Century – became a national catch phrase and a song.

1844 A play opened with the ‘Song’ as a prologue. It drew the public’s attention to the plight of needlewomen.

(Slide) Redgraves ‘Seamstress’ 1846. (see: http://collections.vam.ac.uk/item/O1250737/the-poor-seamstress-watercolour-drawing-redgrave-richard-cb/) One of several picture on the same theme – also Watts and Millais

Seamstresses feature in novels of the 19th century. Romantic feeling about these girls due to ‘there but for the grace of God go I.’ Distressed gentlewomen, or poor middle class, officers and clergymen’s daughters.

Distressed gentlewomen’s association set out to help. The alternative to sweated labour was often prostitution.

Clothes making was one of the major industries of Britain between 1826 and 1914.

The standard of living gradually rose all round – any amelioration of conditions must be set against the gradual rise all round.

Clothing trade seasonal and utilised vast hordes of unemployed – i.e. Irish, Italian, and Jewish immigrants.

Middleman and outworkers system.

18th Century slop shops sold cotton and linen ready made shirts etc. These people became the outfitters of the 19th century and their workers became the sweated labourers as they poached into the tailorer’s trade.

1840s – Tailors strike.

1843 – Poem by Hood.

1844 – Children and Young persons’ act.

1842 – 5,000 women employed in shirt making 4/6 per dozen, at 2 per day

1849 – Henry Mayhew gives more info: ‘The worst work to be had.’ 6d per shirt if good, 2d for bad ones. Wages going down, outworkers.

Early 19th Century shirts like smocks – no curves, in pieces. Low shoulder line, gathered sleeve, gusset under arm. Re-enforced front. Tunic shirts.

Plain sewing was part of every girl’s education. Many miniature garments survive. Best shorts have tucked fronts and little gussets at top of side slits – very finely stitched.

1840s/50s new design in shirts. Raglan sleeves and better shaped. Shirt fronts were worn under waistcoats and jackets with false cuffs – no body to the shirt. A vast variety of shirts, shirt fronts, collars and cuffs – 97 types of shirt, 18 versions of flannel shirts, at least 12 different fronts. Collars and cuffs could be reversible. Paper, celluloid and rubber collar and cuffs available.

Flannel shirts very popular. Striped cotton shorts known as regatta shirts made for 10d per dozen.

Collar and cuff making were a separate trade.

1915 1/5, 4/9, 2/6 per dozen machine made shirts.

London a centre for shirt making, but also Manchester, Glasgow, Taunton, Leeds etc.

By the end of the 19th century Ireland was an important centre for shirt making in factories. Firms came from Glasgow, London, and Manchester to set up factories.

1855 – sewing machines installed for shirt making.

By 1858 200 machines using 200 yards of cotton per day.

Sewing machines expanded the sweating system. Finishing was done by outworkers at home.

It was not possible to unionise outworkers. Could not band together to help themselves.

Sweated industries exhibition 1906.

1909 Trade Boards Act tried to protect these workers.

Army, post office and government departments acted as exploiters, setting minimum wages (only just abolished).

Sarah Levitt was Assistant Curator at the City of Bristol Museum and Art Gallery. Previously Assistant Keeper at Platt Hall, Miss Levitt has an MA in The History of Dress from the Courtauld Institute of Art. Her interest in shirt making stems from research for her book published the month of the conference, Victorians Unbuttoned: Registered Designs for Clothes, their Makers and Wearers.

Women who Wove

Black crape was produced in large quantities in Victorian times for the mourning garments of the middle classes. This session looks at the lives and conditions of working class women and girls employed by Courtaulds in an Essex mill to make the crape.

Notes from a talk by Judy Lown

(Presented at the Costume Society Seminar on ‘Sweated Trades’ Feb 8th 1986)

Courtaulds is one of the ten biggest national textile companies in Britain, and exports all over the world.

Samuel Courtauld started in Essex in 1815.

In the 1820s he had only a handful of workers and made £100 per anum.

By the 1840s he had 400 people in his employ

1850s he moved his family to Gosford Hall, and was aiming to become gentry

In 1881 he died, leaving 2 ½ million pounds.

The family made a fortune out of silk.

Textile work is a female orientated trade.

Essex was a thriving silk producing area in the early 19th century, but by 1860 many firms were extinct. Courtaulds survived, employing 75% of women workers in the mid 19th Century.

Halstead, Bocking, Braintree were silk centres

Essex was formerly a wool producing area – by the late 18th century this trade declined with the concentration in the North, leading to a depression in Essex among females (women having formerly been wool spinners). The Spitalfields silk industry had become chaotic by the late 18th century due to demands for wages. (Silk has always been a female industry from the Middle Ages onwards, but there were no guilds for them. By the late 18th century they were pushed down to lowest earnings.)

Silk manufacturers looked for new places for their industry. Essex was an ideal location and the industry moved there, where there was surplus labour to be taken up, which could be cheaply employed.

The main produce was black silk crepe, with a special weave produced by Courtaulds for the mourning trade.

This had a real boost in 1862 on the death of Prince Albert.

The special machinery developed for this was worked by young people – girls to 17, boys to 15 – silk winding only. Only men were allowed to work the crimping machinery, and the crimping room was kept locked.

Halstead mill workers in the 1850 – women workers wore aprons, with male overseers. Men were engineers and mechanics.

The mills were 3 miles apart and material was transported from one mill to another for different processes. Men were employed as drivers and waggoneers.

There were fines for being late and if they were 5 minutes late they had to wait 15 (before being allowed to start work?)

There were rules about not wearing crinolines which were considered dangerous (machinery) and indecent (when standing up on machinery).

(The family (Courtaulds?) were Unitarians with radical traditions, but were opposed to protective legislation – they felt that employers should create a family atmosphere in mills, not rely on the law).

Middle-class families were realising the ideal of ‘woman in the home.’ This threw up the position of working class women who needed to work. The ‘patriarchal family’ system kept women at the bottom of lists. There was a good deal of concern about working women not learning domestic arts.

A school was set up in the factory for young women. Mary Merryweather was the school teacher. She kept a diary, recording: 120 girls first week – free – class overfull. Girls were noisy and unruly. No womanly constraint.

A nursery was provided. Rules were strict but not understood by women who did not agree with too much clothes changing. It only ran for 3 years.

Other innovations included a room being provided for meals, and an Amusement society (in the late 19th century) – an early social club.

Dr Judith Lown was working full-time for the ILEA in their Adult Education Training Unit, based at the City Literary Institute. Dr Lown’s research on the Courtaulds silk industry was carried out between 1977 and 1983, and was being written up as a book.

A Species of Slavery: Dress making for High Society in the 19th Century

For young girls preparing for their ‘coming-out’ the choice of spectacular dresses to wear at the prescribed events was a major consideration: this talk is about the women who made these dresses working for long hours undertaking tedious and intricate work for low wages.

Notes from a talk by Joanna Marschnner

(Presented at the Costume Society Seminar on ‘Sweated Trades’ Feb 8th 1986)

Two classes of dressmakers – honourable, and sweated.

1st class – was suitable work for those not fitted to be governesses or similar. Daughters of clergy, middle class etc.

Dressmakers made garments. Milliners made hats, caps, and trimmings.

Apprenticeships lasted 3 years.

March to July were busiest seasons, the highlight being court presentation. Dress required – had written regulations, must have long train, feather headdress and veil. Dresses of silk, tulle, ninon (see: https://en.wikipedia.org/wiki/Ninon ) They were a great consumption of fabric.

1863 – a letter from a dressmaker in the Times described death in the workshop due to overwork. This was Mary Ann Walkley, working at Madam Elise in Regent Street (Princess Alexander was a client there.) (see https://bust.com/style/18808-mary-walkley-death-seamstress.html for a detailed account of this tragedy.)

Girls lived in cubicles in dormitories, 2 girls to a bed.

Workrooms were crowded and un-ventilated. Windows were unopened so as to keep out smuts. There was no chance of exercise, and fresh air was lacking.

Meals were consumed rapidly at irregular hours. They were unappetising. A 12 hour day was normal but in the season could be 6:00am to 11:pm, and sometimes they worked all night for Royal drawing rooms to complete orders.

Trimming dresses and making trains involved standing for long hours.

This case inspired research and many horror were uncovered. The system and conditions undermined health. The mortality rate of needlewomen was thrice that of other classes of occupation. Some hands were dismissed for giving evidence.

Many earnest moves were made to alleviate conditions. Societies formed, and authors wrote of milliners and dressmakers in books. A few employers relaxed their systems and allowed a reduction in hours.

After 1863:

1869 – laws to prevent more than 12 hours for dressmakers, but were difficult to enforce. Customers were responsible by wanting dresses at short notice.

1875 – re-organisation of systems, dressmakers allowed to live out

20th Century – girls still sometimes worked all night to finish orders.

Investigations into conditions started in 1842, but nothing much done or brought to public attention until 1863 after death of M.A. Walkley

In 1863 1 hand, plus 1 apprentice took 1 day to complete a dress.

Many witnesses of the 1860s said that conditions had improved from the 1840s

By 1870s day work (non living-in) was becoming more common. However, senior hands still lived in.

Much of this work was done by hand. Sewing machine work was very unpopular, and it was mainly used for foundation work and skirts.

Joanna Marschner was (at the time of the conference) Assistant curator of the Court Dress collection, Kensington Palace. She had previously been Museum Assistant in the Department of Costume and Textiles at the Museum of London.

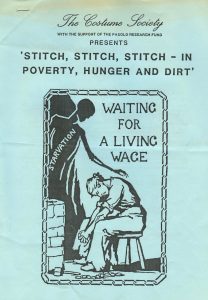

Stitch, Stitch, Stitch – In Poverty, Hunger, and Dirt

In February, 1986, the Costume Society, in association with the Pasold Research Fund, presented a ‘Sweated Trades’ seminar, focusing on the harsh realities which produced the handsome clothes of the 19th Century, and the Victorian age in particular. The presentations considered how seamstresses, employers, and, for that matter, the wearers, were locked together by the rigid bonds of Society.

My mother attended the seminar, and made notes during the lectures, some of which will have informed her own work over the years. Those notes will be transcribed as a series of entries in this Blog, more or less as they were written thirty years ago.

The Seminar was framed by ‘The Song of the Shirt’ – a poem by Thomas Hood (1799 – 1845), in which an overworked, underpaid seamstress laments the harshness of her life:

With fingers weary and worn

With eyelids heavy and red,

A woman sat; in unwomanly rags,

Plying her needle and thread.

Stitch – Stitch – Stitch!

In poverty, hunger and dirt,

And still with a voice of dolorous pitch

She sang ‘The Song of the Shirt.’

The full text of ‘The Song of the Shirt’ can be found on the Victorian Web: http://www.victorianweb.org/authors/hood/shirt.html

(See also: http://www.victorianweb.org/index.html for other resources concerning the period.)

The papers presented were:

‘A Species of Slavery.’ Dressmaking for High Society in the 19th Century – Presented by Joanna Marschner

‘Women who Wove’ – Presented by Judy Lown

‘Shirtmaking’ – Presented by Sarah Levitt

‘The Beaders’ – Presented by Joan Edwards

‘Clothes and Disease. 1830 – 1880’ – Presented by Lou Taylor

‘Fashion Slaves’ – Presented by Christina Walkley

And

‘The Sweating System – The Employers point of view.’ – Presented by Madeleine Ginsburg

Notes from these presentations will follow, each as a separate post. Their contents may be of interest to anyone writing, researching, or even role-playing, in 19th Century settings. Writers of Victorian crime, fictional social history, or fantasy may find ideas for settings, characters, or even plot. Steampunk aficionados may wish to consider just who made their wonderful outfits, and how much they were paid/rewarded.

These are just notes, and are presented as starting points for personal research, rather than comprehensive facts. Where relevant, web links will be added to help point interested parties at further avenues of research.